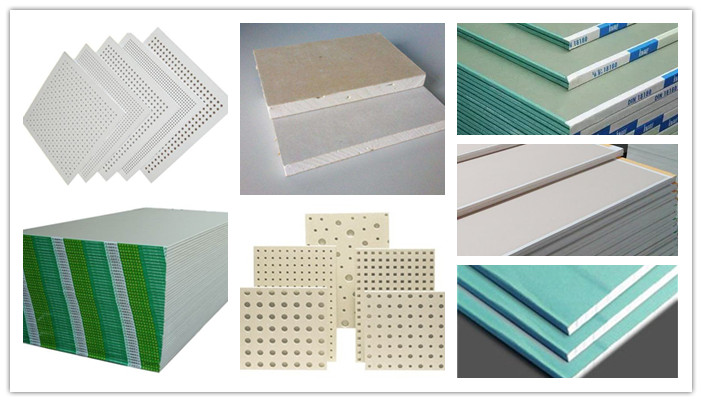

Plasterboard/Gypsum board industry

In gypsum board production, it is need to add binder to gypsum slurry. During board drying process, the binder has migration activity, which will transfer to the lap interface of protective paper board and gypsum core with evaporation of water

Usage and dosage

1. Dry powder add, dosage is 1% of gypsum (Weigh separately, then mix with gypsum powder)

2. Wet add, dosage is 0.5%--0.8% of gypsum (mix with water, then add into gypsum)

Besides, dosage has indirect or direct relationship with air permeability, degree of sizing and water absorption of protective paper, specification and varities of gypsum, air humidity, gypsum board molding and drying method, and thickness of board, etc.. It should be mastered flexibly in the production process, and stable and accurate addition quantity should be found through practice.

Functions and advantages

1. The gelatinization temperature of acid modified starch is low, which can be adequately gelatinized in the drying process of gypsum board

2. The formed paste has stable viscosity, good adhesion, stable performance, and ehances interlayer adhesion and breaking strength

3. Good water resistance, easy to form a transparent film, effectively prevent the gypsum board’s collapse caused by dampness

4. Our company’s acidized starch is produced with wet production method, which makes it has high purity and stability, and also help save the dosage

Applications

1. Acidized starch is widely used in producing plasterboard without mortar for wall construction, various gypsum board with paper surface

2. Oxidized starch is also widely used in gypsum board with fiber

![Factory of oxidized starch and acid modified starch for gypsum board production]()

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!